| The Home page of ILPI's Safety Data Sheet (SDS) Resource, the leader in SDS information since 1995! | |

| The history and philosophy behind this resource. | |

| A curated collection of books and reference materials concerning Safety Data Sheets and closely related topics. | |

| Paste your plain text SDS into the SDS-Demystifier, and it will be converted into a hypertext-enriched document with links to detailed explanations of each key term. | |

| An extensive list of frequently asked questions about Safety Data Sheets including regulations, content, compliance, and more. | |

| A humorous take on Safety Data Sheet jargon. Fill in the blanks on our entry form to generate a personalized Unsafety Data Sheet to share with your coworkers. | |

| Since 1995, we've maintained this massive curated list of the best places to find Safety Data Sheets on the Internet. | |

| You are here! Way more than a glossary, this hypertext-enhanced resource covers hundreds of SDS-related terms and expert knowledge. Each entry includes both the SDS relevance and links to additional authoritative resources. | |

| Archived results of Safety Data Sheet related polls taken by some of our millions of site visitors | |

| The OSHA regulations behind SDS regulations, including the inspection guidelines and over 400 official interpretations letters under the Hazard Communication Standard | |

| Commercial suppliers of SDS authoring and management software as well as cloud compliance services. | |

| Commercial companies that will create SDS's for your specific needs as well as SDS translation companies. |

Safety signs, banners, and scoreboards? Get yours at Safety Emporium!

Definition

Get your SDS binders, centers and more from Safety Emporium.

Hazard Classification is a process required under paragraph (d) of 29 CFR 1910.1200 (the OSHA Haz-com standard) Specifically:

"...For each chemical, the chemical manufacturer or importer shall determine the hazard classes, and where appropriate, the category of each class that apply to the chemical being classified...Chemical manufacturers, importers or employers classifying chemicals shall identify and consider the full range of available scientific literature and other evidence concerning the potential hazards. There is no requirement to test the chemical to determine how to classify its hazards. Appendix A to §1910.1200 shall be consulted for classification of health hazards, and Appendix B to §1910.1200 shall be consulted for the classification of physical hazards.

Note: Under the now-obsolete 1994 version of the standard, this process was far less rigorous and called hazard determination. Hazard classifications replaced hazard determinations with the issuance of the current (2012) version of the standard.

Classification lists the specific Classes of hazards, for example carcinogenicity or flammable solid.

Within the Hazard Classes the degree of hazard is indicated with a Category. The Category is usually a number (1-4) or letter (A, B, C) although there are few that are indicated with words. 1 indicates a greater hazard category than 2, and A is a greater hazard than B. Some of the numeric categories have subcategories, so Class 2A is more hazardous than Class 2B, for example. For gases and some reproductive toxins, the categories are listed by names rather than numbers or letters.

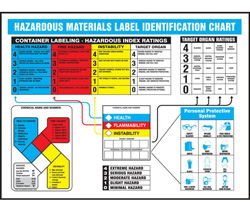

This ranking system where 1 = the greatest hazard and 4 = the least is the exact opposite of the NFPA and HMIS® systems, and is a serious potential point of confusion for untrained workers. Further, as can be seen in the next section, not all hazard classes have entries 1-4; some have only category 1, some have 1-2, 1-3 or 1-4, and Explosives is broken into 6 divisions!

Editorial aside: We have no idea how a respected agency like the UN could come up with such a muddled and inconsistent ranking system. Seriously, couldn't they have labeled everything with names - why not Highest, Severe, Moderate, and Low so people wouldn't have to deal with figuring out what numbers and letters mean? How hard would that have been?

Additional Info

In a hazard classification, only the intrinsic (inherent) hazardous properties of chemicals are considered. The three steps involved are:

Encourage safety on the job with electronic safety scoreboards from Safety Emporium.

- Identification of relevant data regarding the hazards of a chemical;

- Subsequent review of those data to ascertain the hazards associated with the chemical;

- Determination of whether the chemical will be classified as hazardous and the degree of hazard.

The specific Health hazard criteria to be reviewed are:

- Acute toxicity (oral, Dermal and Inhalation), Categories 1-4

- Skin corrosion / Irritation, Categories 1A, 1B, 1C, and 2

- Serious eye damage / eye Irritation, Categories 1, 2A, and 2B

- Respiratory or Skin Sensitization, Category 1A and 1B

- Germ cell Mutagenicity, Categories 1A, 1B, and 2

- Carcinogenicity, Categories 1A, 1B, and 2

- Reproductive toxicity, Categories 1A, 1B, 2; lactation

- Specific Target organ Toxicity: single exposure, Categories 1-3

- Specific Target organ Toxicity: repeated or prolonged exposure, Categories 1 and 2

- Aspiration hazard, Category 1

Appendix F to §1910.1200 provides specific further guidance for the carinogenicity assignment. The specific Physical hazard criteria to be reviewed are:

- Explosives, Divisions 1.1-1.6

- Flammable gases, Categories 1 and 2

- Flammable aerosols, Categories 1 and 2

- Oxidizing gases, Category 1

- Gases under pressure, Groups: compressed, liquified, dissolved, refrigerated liquid

- Flammable liquids, Categories 1-4

- Flammable solids, Categories 1 and 2

- Self-reactive chemicals, Types A-G

- Pyrophoric liquids, Category 1

- Pyrophoric solids, Category 1

- Self-heating chemicals, Categories 1 and 2

- Chemicals which, in contact with water, emit flammable gases, Categories 1-3

- Oxidizing liquids, Categories 1-3

- Oxidizing solids, Categories 1-3

- Organic Peroxides, Types A-G

- Corrosive to metals, Category 1

The GHS model standard on which current OSHA regulations are

Keep informed about workplace hazards with proper labeling techniques and safety posters available from Safety Emporium.

Several sections of 29 CFR 1910.1200 and the appendices deal with the complexity involved in assessing mixtures. A quick summary is:

- Test data can be used if it is available, but no testing is required.

- Bridging principles can be used to estimate the degree of hazard based on the hazards of the mixture components.

- If all else fails, there are technical methods to estimate the hazard classification.

SDS Relevance

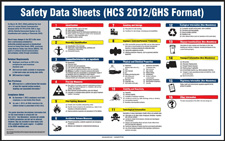

The hazards found in the classification process must be communicated using the Safety Data Sheet (SDS) and label. These are reflected in:

- Pictograms which convey the hazards

- Signal words (Danger or Warning)

- Hazard statements

- Precautionary statements

Of course, there are other required elements for the SDS and label. And the information contained in the SDS and label will be part of the training required for those employees who use or could be exposed to the material.

Classification is performed by the author of the sheet; there is no need for employers to perform an hazard classification of their own unless they are the manufacturer of the material. If you are a downstream user of the sheet, you are allowed to rely on the classification on the materials that you received.

Given that the complexity of the hazard classifications that must be communicated to your employees, a poster as well as training that explain the meanings of the various pictograms and such is a very good idea.

Ensure your workers are trained with safety posters and more at Safety Emporium.

Further Reading

- Classification and Labelling Summary Tables for the GHS at UNECE.

- WHMIS 2015 - Hazard Classes and Categories at the Canadian Centre for Occupational Health & Safety.

- GHS - OSHA HCS Comparison; Comparison of Hazard Communication Requirements at US OSHA.

- GHS Hazardous Chemical Information List at Safe Work Australia contains a list of chemicals and their classifications.

- GHS Classification summary at the US NIH.

- Chemical Hazard Classification (GHS) at the U of Illinois Division of Research Safety.

See also: toxic, carcinogen.