| The Home page of ILPI's Safety Data Sheet (SDS) Resource, the leader in SDS information since 1995! | |

| The history and philosophy behind this resource. | |

| A curated collection of books and reference materials concerning Safety Data Sheets and closely related topics. | |

| Paste your plain text SDS into the SDS-Demystifier, and it will be converted into a hypertext-enriched document with links to detailed explanations of each key term. | |

| An extensive list of frequently asked questions about Safety Data Sheets including regulations, content, compliance, and more. | |

| A humorous take on Safety Data Sheet jargon. Fill in the blanks on our entry form to generate a personalized Unsafety Data Sheet to share with your coworkers. | |

| Since 1995, we've maintained this massive curated list of the best places to find Safety Data Sheets on the Internet. | |

| You are here! Way more than a glossary, this hypertext-enhanced resource covers hundreds of SDS-related terms and expert knowledge. Each entry includes both the SDS relevance and links to additional authoritative resources. | |

| Archived results of Safety Data Sheet related polls taken by some of our millions of site visitors | |

| The OSHA regulations behind SDS regulations, including the inspection guidelines and over 400 official interpretations letters under the Hazard Communication Standard | |

| Commercial suppliers of SDS authoring and management software as well as cloud compliance services. | |

| Commercial companies that will create SDS's for your specific needs as well as SDS translation companies. |

Safety signs, banners, and scoreboards? Get yours at Safety Emporium!

Be sure you're in compliance with DOT placards and labels from Safety Emporium.

Definition

As an adjective, explosive refers to a chemical compound, mixture, device etc. that is capable of exploding. For example: "Gasoline forms an explosive mixture with air."

As a noun, explosive is a compound or mixture susceptible (by heat, shock, friction or other impulse) to a rapid chemical reaction, decomposition or combustion with the rapid generation of heat and gases with a combined volume much larger than the original substance.

Explosives can be broken into two general categories that reflect the rate of the transformation.

- High explosives are capable of detonating and are used in military ordinance, blasting and mining etc.. These have a very high rate of reaction, high pressure development, and the presence of a detonation wave that moves faster than the speed of sound (1,400 to 9,000 meters per second). Examples include primary explosives such as nitroglycerin that can detonate with little or no stimulus and secondary explosives such as dynamite (trinitrotoluene, TNT) that require a strong shock (from a detonator such as a blasting cap).

- Low explosives change into gases by burning or combustion. These are characterized by deflagration (burning rapidly without generating a high pressure wave) and a lower reaction rate than high explosives. The overall effect ranges from rapid combustion to a low order detonation (generally less than 2,000 meters per second). Gun powder (black powder) is the only common example.

Additional Info

Vent your flammable storage safety cabinets safely with Safe-T-Vent thermally-actuated dampers from Safety Emporium.

A detailed discussion of explosives such as gunpowder, TNT etc. is outside the purview of this resource, but a few key points are worth mention, all of which follow from the cardinal principle of explosive safety, expose the minimum number of people to the minimum amount of explosive for the minimum amount of time. If you are working with explosives or potentially explosive materials (for example, in a laboratory setting using peroxides, azides, or other high-energy compounds), take the necessary precautions to limit the size/scale/scope of your work to the absolute minimum required. Be wary of potential spark and ignition sources such as electric outlets (use only Class 1 Division 1 explosion-proof electrical fixtures), static discharge, friction, exothermic reactions etc. and take proper precautions for storage and handling such as powder magazines, and safety enclosures.

A stunning example of laboratory work involving high energy materials gone wrong occurred at Texas Tech University in 2010, causing severe injuries to a graduate student worker that included the loss of three fingers. A US Chemical Safety Board case study of that incident provides useful lessons and recommendations for anyone working with similar materials.

SDS Relevance

Explosive can appear on Safety Data Sheets in a wide variety of contexts and in multiple sections of a sheet.

Flammable vapors can form explosive mixtures with air under certain circumstances. Accidental ignition by a spark, heat source or static electricity can trigger an explosion. These vapors can travel a significant distance from their source (along hallways and stairwells, for example), so always be sure to reduce or eliminate vapor formation whenever possible.

Some materials are shock-sensitive, meaning that they can be detonated (explode) merely by friction or touch. Examples include organic peroxides, nitrogen triiodide and dry picric acid. Such materials should only be dealt with by explosives-trained experts.

Other explosions can be caused by mixing incompatible chemicals. This is a common sort of laboratory accident (and one of the most terrifying).

Explosions can also be caused by over-pressurized containers. There is an utterly remarkable account of a large liquid nitrogen Dewar explosion at Texas A&M University that demolished a laboratory and rocketed through the concrete ceiling, leaving a perfect round hole. A similarly catastrophic incident occurred on a Texas highway in 2006 with a liquid oxygen cylinder. On a smaller scale, pressure can build up inside reaction vessels or containers if they are not properly vented, leading to catastrophic failure.

Never rely on the absence of a smell alone to indicate that propane or natural gas vapors are not present, particularly in a confined space. The odorants used in these gases can sometimes fade upon storage; see the entry on anosmia for more information on this phenomenon.

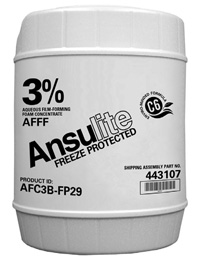

Safety Emporium sells MIL-SPEC fire fighting foam concentrates and other extinguishing agents.

Further Reading

- An example of a real-life laboratory explosion caused by mixing incompatible chemicals.

- The American Chemical Society's journal Chemical & Engineering News maintains a list of Safety Letters concerning materials involved in unexpected explosive decompositions.

- An archived version of the US Geological Survey's The Dictionary or Mining, Mineral and Related Terms.

- The University of Rhode Island's Center of Excellence for Explosives Detection, Mitigation and Response has courses, an Explosives Database and more.

- Anatomy of an Explosion by Kieron Helsdon.

- OSHA has numerous reports of fatal oil tank explosions.

- Lessons to prevent deaths during hot work in, around tanks provides some key lesson and graphic photos from incidents involving improper precautions with potentially explosive vapors.

- Prevention of fires and explosions at OSHwiki, courtesy of EU-OSHA.

- Largest artificial non-nuclear explosions at Wikipedia.