| The Home page of ILPI's Safety Data Sheet (SDS) Resource, the leader in SDS information since 1995! | |

| The history and philosophy behind this resource. | |

| A curated collection of books and reference materials concerning Safety Data Sheets and closely related topics. | |

| Paste your plain text SDS into the SDS-Demystifier, and it will be converted into a hypertext-enriched document with links to detailed explanations of each key term. | |

| An extensive list of frequently asked questions about Safety Data Sheets including regulations, content, compliance, and more. | |

| A humorous take on Safety Data Sheet jargon. Fill in the blanks on our entry form to generate a personalized Unsafety Data Sheet to share with your coworkers. | |

| Since 1995, we've maintained this massive curated list of the best places to find Safety Data Sheets on the Internet. | |

| Way more than a glossary, this hypertext-enhanced resource covers hundreds of SDS-related terms and expert knowledge. Each entry includes both the SDS relevance and links to additional authoritative resources. | |

| Archived results of Safety Data Sheet related polls taken by some of our millions of site visitors | |

| You are here! The OSHA regulations behind SDS regulations, including the inspection guidelines and over 400 official interpretations letters under the Hazard Communication Standard | |

| Commercial suppliers of SDS authoring and management software as well as cloud compliance services. | |

| Commercial companies that will create SDS's for your specific needs as well as SDS translation companies. |

Safety signs, banners, and scoreboards? Get yours at Safety Emporium!

| Title: 04/03/1991 - Emergency response in the trucking industry. | |

| Record Type: Interpretation | Standard Number: 1910.120, 1910.1200 |

April 3, 1991

MEMORANDUM FOR: JAMES W. STANLEY, REGIONAL ADMINISTRATOR

THROUGH: LEO CAREY, DIRECTOR, OFFICE OF FIELD PROGRAMS

FROM: PATRICIA K. CLARK, DIRECTOR, DIRECTORATE OF COMPLIANCE PROGRAMS

SUBJECT: Emergency Response in the Trucking Industry: 1910.1200 vs. 1910.120

This is in response to your inquiry concerning the application of 29 CFR 1910.120 and 29 CFR 1910.1200 at trucking terminals. For the sake of clarity, we are restating your questions before the answers.

- Question: A trucker opens the back of the truck at the trucking terminal to find a container split open with an unknown noxious chemical located on the truck bed. This person is told to go in and clean up the material. The company has no way to characterize the exposure. What level of personal protective equipment should be required and which standards apply.br>

Answer: Based on the limited information you presented several standards could be applicable. The following are some examples:

- Hazard Communication Standard (HCS), 29 CFR 1910.1200:

Train your employees to respond to emergencies with colorful workplace safety posters from Safety Emporium.

- Each container of hazardous chemicals must be labeled, tagged or marked with the identity of the hazardous chemical, an appropriate hazard warning, and the name and address of the chemical manufacturer, importer, or other responsible party. If there is time, and based on the information on the label, the chemical manufacturer or "other responsible party" could be contacted to determine emergency control measures and to estimate "worst-case exposures."

- A Material Safety Data Sheet (MSDS) must accompany each initial shipment of hazardous chemical and must be readily accessible to employees handling the chemical. MSDSs are also sent with the product whenever new information on the chemical necessitates the updating of the MSDS. The Department of Transportation (DOT), however, requires information on the bill of lading for all shipments of hazardous cargo which all drivers must carry. The company could characterize the exposure by the DOT-required information from the driver's bill of lading papers.

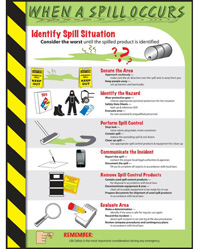

- If there is no potential for an emergency, then training under HCS must include if applicable leak and spill cleanup procedures including appropriate PPE, decontamination procedures and safety precautions, and other training elements required under the HCS standard.

- Hazardous Waste Operations and Emergency Response:

If there is an emergency, or if a trained person capable of determining whether a situation is an emergency or has the potential to be an emergency is not available, (i.e., if "worst-case exposures" have not been estimated) then the situation needs to be treated as an emergency and the provisions of 1910.120 apply as set forth below.

- Prior to the commencement of emergency response procedures, an emergency response plan must be developed and implemented (1910.120(q)(1)).

- If the employer elects to respond himself, the company needs to have someone on hand at each shift who can provide direction with respect to safe response operations for each emergency situation (29 CFR 1910.120(q)(3)(vii)).

- Employees engaged in responding to spills of unknown chemicals presenting an inhalation hazard or potential inhalation hazard must wear the level of respiratory protection which will protect against the worst case possible scenario. Most of the time positive pressure self-contained breathing apparatus will be initially required until such time monitoring data indicates otherwise (see 29 CFR 1910.120(q)(3)(iv)).

- The training under 29 CFR 1910.120(q)(6) depends on the duties and functions to be performed by the truck driver. If the truck driver is expected to stop dangerous leaks and clean up the spills then the training at the hazardous materials technician or hazardous materials specialist level is appropriate.

- Hazard Communication Standard (HCS), 29 CFR 1910.1200:

- Question: Does a freight company have the responsibility of training its employees to be ready to clean up or to respond to an emergency

caused by the opening of a package or container improperly labelled by a customer?

Get your hazardous waste labels from Safety Emporium.

Answer: If a freight company has the potential for receiving hazardous substances in a form, amount, or manner that has a potential for causing an emergency situation then the company falls under the scope of 29 CFR 1910.120(q). The employer can elect to evacuate their employees from the danger area when an emergency occurs and have an emergency action plan in accordance with 29 CFR 1910.38(a) (see 1910.120(q)(1)). If the employer takes a response role then an emergency response plan must be developed. This plan must address, among other elements, personnel roles, lines of authority, training, and communication. The employer has several options on the structure of the emergency response organization. For example, the employer could train all receivers at the first responder awareness level and have a response team that would be called in to respond to emergencies. The receivers could also be trained under the HCS to clean up minor spills and leaks.

- Question: If 1910.1200(h) is cited for training, it requires retraining "whenever a new hazard is introduced into their work area". This could be a daily event in a trucking terminal. Is there a point at which we should require these companies train under both 1910.120 and 1910.1200? How

strict should we interpret this requirement?

Answer: As you are aware, under the HCS if a new chemical is brought into the workplace, and it has hazards similar to existing chemicals for which training has already been conducted, then no new training is required. (See page A-34 of OSHA Instruction CPL 2-2.38C.) If this question is a follow-up to question 2 pertaining to unknown hazards, then the answer depends on what role the employer wants the employees to take during a potential emergency. (Answer to question 2 expands on this.)

The original official public domain version of this document is available from OSHA at https://www.osha.gov/laws-regs/standardinterpretations/1991-04-03-0.