|

|

| MSDS Topics |

Free Sites | FAQ's | Regulations | Glossary | Software | Suppliers |

| Books | Forum | Poll | Fun stuff | Quiz | Store | |

| MSDS and safety supplies | Search ALL our MSDS info | |||||

| |||

|

|

|

|

| Title: 06/10/1991 - Training required for clean-up of hazardous waste and hazardous substances | |

| Record Type: Interpretation | Standard Number: 1910.120; 1910.1200 |

|

June 10, 1991

Mr. Fred Williams Dear Mr. Williams: This is in response to your inquiry of April 13, concerning the Occupational Safety and Health Administration's (OSHA) hazardous Waste Operations and Emergency Response final rule (29 CFR 1910.120) (HAZWOPER) and the Hazard Communication Standard (29 CFR 1910.1200) (HCS). Please accept my apology for the delay in this reply. Thank you for your interest in these regulations and for your dedication to insuring a safe and healthful work place for you and your colleagues. Your first question relates to the scope of 1910.120 and 1910.1200. It reads as follows:

| (sponsored information) 400,000 MSDS's in your shirt pocket... |

|

There are exceptions to paragraphs (p)(1) through (p)(7) which are discussed in attachment A to this letter. It appears from your letter that hazardous waste is stored at your facility for less than 90 days. Therefore, your facility may not be required to have a RCRA permit. If that is the case, paragraphs (p)(1) through (p)(7) of 1910.120 would not be required of your employers. Paragraph (p)(8) and/or (q) of 1910.120 would apply to your workplace if the employees are at substantial threat of releases of the hazardous substances you listed in your letter and provide emergency response. Paragraph (p)(8) applies in areas used for treatment, storage or disposal of hazardous waste. In other areas not used primarily for treatment, storage or disposal of hazardous waste, any employers with employees involved in emergency response operations must comply with (q). The employer may choose to comply with (q) throughout the facility which would satisfy the requirements of paragraph (p)(8). There are also exceptions to some of paragraph (q) requirements that are discussed in attachment B to this letter. Paragraph (q) of 1910.120 requires different levels of training depending on the employees assigned role during an emergency response. The required training and competencies for each level of emergency response are described in detail in paragraph (q)(6) of the final rule, which is enclosed.

|  Protect your workers from dangerous fumes with supplied air respirator systems like this one from Safety Emporium. |

The Hazard Communication Standard (HCS) also requires training for employees exposed or potentially exposed to hazardous chemicals. The Hazard Communication Standard does not, however, cover hazardous wastes as defined and regulated by the EPA. For other hazardous chemicals known to be present at the workplace, the standard states that health hazard information is required to be transmitted from the chemical manufacturer or importer and flow "downstream" with the substance as it is used by industry.

For your further information, I am enclosing the OSHA booklet "Chemical Hazard Communication" which will provide you with information on the requirements of the HCS, including required workplace training.

In general, "hazardous materials generators who are using, packaging and transporting hazardous materials" may be required to train their employees by 1910.1200 and by 1910.120, depending on the chemicals they work with and the actions they are required to take during an emergency. The content and objective of the required training from the two standards are different.

|

The required Hazard Communication covers all employees who work near chemicals. It requires the employer to train workers about work place specific safety and health hazards, how the employee can access information pertaining to those hazards and how the employee can use the information effectively to protect his or her health. The Hazard Communication Standard has limited training requirements with regard to emergency procedures. The employer must provide employees with training on recognizing hazardous incidents and how to evacuate during an emergency. In contrast, HAZWOPER only covers employees at hazardous waste sites, Treatment, Storage and Disposal Facilities and those employees that will respond during to emergencies involving the spill of hazardous material. For emergency responders there are five different levels of training for five different levels of responsibility during an emergency response. These levels and training requirements for each can be found in paragraph (q)(6) of the final rule which is enclosed.

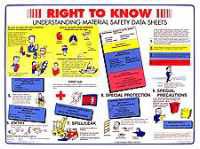

|  Teach your employees about MSDS's with posters and pamphlets from Safety Emporium. |

[This document was edited on 07/27/00 to strike information that no longer reflects current OSHA policy.]

Sincerely,

Patricia K. Clark, Director

Directorate of Compliance Programs

Enclosures

Attachment A

Exceptions to the hazardous Waste Operations and Emergency Response Final Rule (1910.120), as amended April 13, 1990.

HAZWOPER was amended April 13, 1990, and the following exceptions to training requirements were more clearly delineated in corrected paragraph (a)(2)(iii). The exceptions sub paragraph reads as follows:

Notes and Exception:

|

The Resource Conservation and Recovery Act defines a conditionally exempt small quantity generator in section 261.5, which reads as follows:

|  Get your spill control pallets and more at Safety Emporium. |

The provisions include storing wastes in RCRA approved tanks and containers, which must be labeled with the start date of accumulation, and have a sign identifying the container as containing "Hazardous Waste".

For more information in the specific provisions entailed in (a) above, or for general information concerning the Resource Conservation and Recovery Act (RCRA) call theRCRAHotline at 1-800-424-9346 from 8:30 am to 7:30 pm eastern standard time.

Attachment B

Mark the location of your emergency and safety equipment with signs from Safety Emporium. |

Exceptions from paragraph (q) of the Hazardous Waste Operations and Emergency Response Final Rule (1910.120), as amended April 13, 1990. There are two areas relating to exceptions from the requirements of 1910.120 paragraph (q). Incidental spills in manufacturing locations that could be cleaned-up or stabilized by employees working in the immediate spill area without need of a coordinated spill control response are not considered emergency incidents under 29 CFR 1910.120 and therefore do not require employees to be trained. Such employees would have training requirements under the Hazard Communication Standard (1910.1200) and other appropriate training made necessary by the tasks they are expected to perform. |

An additional exception from paragraph (q) requirements can be found in paragraph (q)(1) which reads:

Attachment C

April 13, 1991

OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION

COMPLIANCE DEPARTMENT WASHINGTON, DC

To whom it may concern:

My name is Fred Williams and I am employed by Martin Marietta Energy Systems Inc of Piketon Ohio. I work in the Instrument Dept Metrology Lab and use certain Chemicals, which I have a partial listing of these Chemicals on the preceding page. In the everyday use of these Chemicals we generate waste, which we treat as hazardous Waste and are required to transport this waste to a 90 day hazardous Waste storage area.

|

To date there is a difference of opinion, between Myself and the Company, as to the training required for a hazardous Waste Generator who uses, packages and/or transports this hazardous Waste. I have listed five questions on the preceding page, for which I feel, will help to remove the difference of opinion once and for all on both sides. I would appreciate your reply to each question I have listed and any other information you may feel will help. I am the Union Steward for the Instrument Dept and have tried to work with the Company in securing the answers to these questions from your office and to date I have only received road blocks. It seems we are the only ones who are concerned about the answers to these questions. I have recently spoke with Wendel Glasier, OSHA, and our conversation prompted me to secure the proper interpretation of these questions from you. I feel that you, as the Subject Matter Experts, will be able to remove any concern the Company or Myself may have in the interpretation of the stated laws. Thank you for all your time and concern.

|

Working at a remote location? Portable eye wash units from Safety Emporium can help meet OSHA requirements. |

Sincerely,

Fred Williams

April 13, 1991

OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION % COMPLIANCE DEPARTMENT WASHINGTON, DC

ACIDS: HC1, H2SO4, HNO3, SOLVENTS: Isopropanol, Acetone, MEK, Freon-113, 1,1,1-TCA, Mercury, Fluorine (Acute) Glycerin Potassium Sodium Tartrate, H2O2, Paint, NH4OH, Phosphoric Acid, NaClO4, Ammonium Carbonate, Lye (NaOH), Acetone, Soldering Flux (Fluoride Salts)

Fred Williams

6771 Straight Creek Road

Waverly, Ohio 45690

The official, public domain, OSHA version of this document is available at http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=INTERPRETATIONS&p_id=20295&p_text_version=FALSE