|

|

| MSDS Topics |

Free Sites | FAQ's | Regulations | Glossary | Software | Suppliers |

| Books | Forum | Poll | Fun stuff | Quiz | Store | |

| MSDS and safety supplies | Search ALL our MSDS info | |||||

| |||

|

|

|

|

| Title: 06/27/1990 - "Guidelines for the preparation of warning labels for carbon and graphite electrical products". | |

| Record Type: Interpretation | Standard Number: 1910.1200 |

June 27, 1990

Mr. Richard E. Opatick

Section Staff Executive

National Electrical Manufacturers Association

2101 L Street, N.W.

Suite 300

Washington, D.C. 20037-1581

Dear Mr. Opatick:

Thank you for your letter of May 16 which transmitted a copy of "Guidelines for the Preparation of Warning Labels for Carbon and Graphite Electrical Products" as developed by the Carbon and Manufactured Graphite Sections of the National Electrical Manufacturers Association (NEMA).

OSHA does not approve nor does it endorse documents such as the one you submitted for Agency "review and comment." My staff has, however, made a very cursory review of the proposed guidelines and has noted some changes and comments directly on the margins and text of the enclosed document which we are returning to you.

As you may be aware, a significant legal decision with specific regard to the labeling requirements of OSHA's Hazard Communication Standard (HCS) was set forth on November 8, 1988, when the U.S. Court of Appeals for the District of Columbia upheld OSHA's interpretation of the labeling requirements of the Hazard Communication Standard (General Carbon Co. v. OSHRC, 860 F. 2d 479 (D.C. Cir. 1988)). The case in point arose out of an OSHA citation against the General Carbon Company for failing to label containers of electrical brushes containing copper and graphite with information about health hazards associated with exposure to copper and graphite dust. General Carbon stipulated that copper and graphite were "hazardous chemicals" within the meaning of the standard, but argued that it would be unreasonable to require labeling in this case because the amount of copper and graphite dust released by the brushes did not endanger the health of employees.

The Court of Appeals concluded that the standard requires labeling based on the intrinsic properties of hazardous chemicals, not on predictions about the level of risk experienced by particular employees. As stated in the court's decision, "[U]nder the definition given in the HCS, an identification of a substance as a hazardous chemical does not depend upon the product's anticipated use at any particular worksite. A substance (e.g., copper or graphite) either is or is not a hazardous chemical; the HCS definition cannot be read to indicate that a substance could be a hazardous chemical in some concentrations but not in others."

The court also ruled that (1) because they release more than a few molecules of carbon and graphite, the brushes were not articles exempt from coverage, and (2) the violation could not be characterized as de minimis, because such a characterization would be inconsistent with the premise of the standard, that "as a general matter, providing workers with comprehensive information regarding possible workplace dangers bears a direct and immediate relationship to safety and health."

It is OSHA policy that exposure calculations are not permitted in determining whether a hazard must appear on a label. If there is a potential for exposure, other than in minute or trace quantities, the hazard must be included when well-substantiated. Suppliers may not exclude hazards based on presumed levels of exposure downstream (i.e., omitting a carcinogenic hazard warning because, in the supplier's estimate, presumed exposures will not be high enough to cause the effect). The General Carbon decision highlights the fact that the hazard is an intrinsic property of the chemical. Exposure determines degree of risk and should be addressed in training programs by the downstream employer.

In the recent decision in Durez Division of Occidental Chemical Corp. v. OSHA, No. 89-1585 (D-.C. Cir., June 19, 1990), the D.C. Circuit Court affirming its decision in General Carbon, again deferred to the Agency's interpretation that a downstream employer is better able than the manufacturer of a chemical to adjust health warnings to the needs of his own workplace.

|

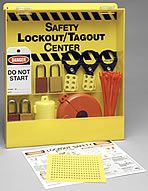

We encourage you to stress these principles in your guidelines to NEMA member companies. It is also important to emphasize in these guidelines that the manufacturer or importer of a hazardous chemical as defined under the HCS is the responsible party for performing the hazard evaluation on his product. This evaluation must assess the hazards associated with actual or potential worker exposures, including all routes of entry, that may occur during the normal use of the product or in foreseeable emergencies. The information obtained from this assessment, i.e., the potential exposures that may occur with the use of the product, is the basis for the information that must appear on a chemical product's label. Further, the hazard warning must convey the hazard of the chemical as expressed by including its target organ effects on the label. The issue of target organ effects is discussed in detail in OSHA's Instruction CPL 2-2.38B which is included in your document (see page 5). We hope this discussion has been helpful to you in the development of these guidelines and encourage you to continue your efforts in promoting effective hazard communication information among your member companies. |  Control of hazardous energy is critical in providing a safe workplace. Get your lockout/tagout supplies at Safety Emporium. |

Patricia K. Clark, Director Designate

Directorate of Compliance Programs

The official, public domain, OSHA version of this document is available at http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=INTERPRETATIONS&p_id=20026&p_text_version=FALSE