Fire polishing the ends of glass tubing and rod will seal small cracks in the end wall, reducing the chance of fractures originating from this source. Fire polishing ends will also reduce cuts and abrasions to you or anything (corks, latex tubing, etc.) coming in contact with the glass end. Try the following:

- Cut 10 mm tubing into 16 inch lengths (or use tubing from a previous lesson)

- Light your torch and adjust the flame to sharp and soft.

- Fire polish by rotating the glass tube end in the flame.

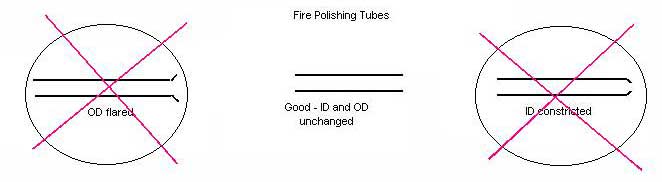

- A good fire polish has a smooth finish and the ID and OD of the glass tube remains unchanged.

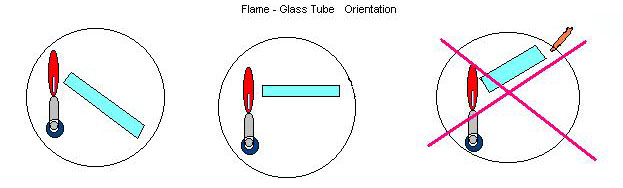

| Tip: Hold the glass tube in a declining or horizontal position with the tube end angled away from you. This will prevent the flame from traveling up the tube and out the far end, possibly resulting in a burn. |