| The Home page of ILPI's Safety Data Sheet (SDS) Resource, the leader in SDS information since 1995! | |

| The history and philosophy behind this resource. | |

| A curated collection of books and reference materials concerning Safety Data Sheets and closely related topics. | |

| Paste your plain text SDS into the SDS-Demystifier, and it will be converted into a hypertext-enriched document with links to detailed explanations of each key term. | |

| An extensive list of frequently asked questions about Safety Data Sheets including regulations, content, compliance, and more. | |

| A humorous take on Safety Data Sheet jargon. Fill in the blanks on our entry form to generate a personalized Unsafety Data Sheet to share with your coworkers. | |

| Since 1995, we've maintained this massive curated list of the best places to find Safety Data Sheets on the Internet. | |

| Way more than a glossary, this hypertext-enhanced resource covers hundreds of SDS-related terms and expert knowledge. Each entry includes both the SDS relevance and links to additional authoritative resources. | |

| Archived results of Safety Data Sheet related polls taken by some of our millions of site visitors | |

| You are here! The OSHA regulations behind SDS regulations, including the inspection guidelines and over 400 official interpretations letters under the Hazard Communication Standard | |

| Commercial suppliers of SDS authoring and management software as well as cloud compliance services. | |

| Commercial companies that will create SDS's for your specific needs as well as SDS translation companies. |

Safety signs, banners, and scoreboards? Get yours at Safety Emporium!

Guidelines for Employer Compliance (Advisory)

Appendix E to the Hazard Communication Standard, 29 CFR 1910.1200

[Note: Annotations made in green text below are tips/commentary by ILPI, not OSHA.]

| This version of the OSHA HazCom Standard is no longer valid. It is presented here solely for historical purposes and has been replaced by a new version effective May 25, 2012. The subjects of the Appendices have also changed. |

Table of Contents

- Introduction to the HCS

- A Simplified Compliance Outline For Employers

Introduction to the HCS

Ensure your workers are trained with safety posters and more from Safety Emporium.

The Hazard Communication Standard (HCS) is based on a simple concept - that employees have both a need and a right to know the hazards and identities of the chemicals they are exposed to when working. They also need to know what protective measures are available to prevent adverse effects from occurring. The HCS is designed to provide employees with the information they need.

Knowledge acquired under the HCS will help employers provide safer workplaces for their employees. When employers have information about the chemicals being used, they can take steps to reduce exposures, substitute less hazardous materials, and establish proper work practices. These efforts will help prevent the occurrence of work-related illnesses and injuries caused by chemicals.

The HCS addresses the issues of evaluating and communicating hazards to workers. Evaluation of chemical hazards involves a number of technical concepts, and is a process that requires the professional judgment of experienced experts. That's why the HCS is designed so that employers who simply use chemicals, rather than produce or import them, are not required to evaluate the hazards of those chemicals. Hazard determination is the responsibility of the producers and importers of the materials. Producers and importers of chemicals are then required to provide the hazard information to employers that purchase their products.

Employers that don't produce or import chemicals need only focus on those parts of the rule that deal with establishing a workplace program and communicating information to their workers. This appendix is a general guide for such employers to help them determine what's required under the rule. It does not supplant or substitute for the regulatory provisions, but rather provides a simplified outline of the steps an average employer would follow to meet those requirements.

[Document index (top of page)]

| This version of the OSHA HazCom Standard is no longer valid. It is presented here solely for historical purposes and has been replaced by a new version effective May 25, 2012. The subjects of the Appendices have also changed. |

A Simplified Compliance Outline For Employers

- "Becoming Familiar With The Rule."

Your employees can stay informed and safety-ready with right to know stations and labels from Safety Emporium.OSHA has provided a simple summary of the HCS in a pamphlet entitled "Chemical Hazard Communication," OSHA Publication Number 3084 [ILPI's tip: you can download this in PDF format at http://www.osha.gov/Publications/osha3084.pdf, 254K]. Some employers prefer to begin to become familiar with the rule's requirements by reading this pamphlet. A copy may be obtained from your local OSHA Area Office, or by contacting the OSHA Publications Office at (202) 523-9667.

The standard is long, and some parts of it are technical, but the basic concepts are simple. In fact, the requirements reflect what many employers have been doing for years. You may find that you are already largely in compliance with many of the provisions, and will simply have to modify your existing programs somewhat. If you are operating in an OSHA-approved State Plan State, you must comply with the State's requirements, which may be different than those of the Federal rule. Many of the State Plan States had hazard communication or "right-to-know" laws prior to promulgation of the Federal rule. Employers in State Plan States should contact their State OSHA offices for more information regarding applicable requirements.

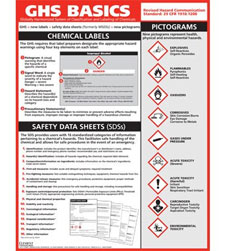

The HCS requires information to be prepared and transmitted regarding all hazardous chemicals. The HCS covers both physical hazards (such as flammability), and health hazards (such as irritation, lung damage, and cancer). Most chemicals used in the workplace have some hazard potential, and thus will be covered by the rule.

One difference between this rule and many others adopted by OSHA is that this one is performance-oriented. That means that you have the flexibility to adapt the rule to the needs of your workplace, rather than having to follow specific, rigid requirements. It also means that you have to exercise more judgment to implement an appropriate and effective program.

The standard's design is simple. Chemical manufacturers and importers must evaluate the hazards of the chemicals they produce or import. Using that information, they must then prepare labels for containers, and more detailed technical bulletins called material safety data sheets (MSDS).

Chemical manufacturers, importers, and distributors of hazardous chemicals are all required to provide the appropriate labels and material safety data sheets to the employers to which they ship the chemicals. The information is to be provided automatically. Every container of hazardous chemicals you receive must be labeled, tagged, or marked with the required information. Your suppliers must also send you a properly completed material safety data sheet (MSDS) at the time of the first shipment of the chemical, and with the next shipment after the MSDS is updated with new and significant information about the hazards.

You can rely on the information received from your suppliers. You have no independent duty to analyze the chemical or evaluate the hazards of it. [ILPI tip: Here's the official word from OSHA on that: CPL 2-2.38D - Inspection Procedures for the Hazard Communication Standard]

Employers that "use" hazardous chemicals must have a program to ensure the information is provided to exposed employees. "Use" means to package, handle, react, or transfer. This is an intentionally broad scope, and includes any situation where a chemical is present in such a way that employees may be exposed under normal conditions of use or in a foreseeable emergency.

The requirements of the rule that deal specifically with the hazard communication program are found in this section in paragraphs (e), written hazard communication program; (f), labels and other forms of warning; (g), material safety data sheets; and (h), employee information and training. The requirements of these paragraphs should be the focus of your attention. Concentrate on becoming familiar with them, using paragraphs (b), scope and application, and (c), definitions, as references when needed to help explain the provisions. [ILPI tip: check out our MSDS Hyperglossary and FAQ if you need additional help]

There are two types of work operations where the coverage of the rule is limited. These are laboratories and operations where chemicals are only handled in sealed containers (e.g., a warehouse). The limited provisions for these workplaces can be found in paragraph (b) of this section, scope and application. Basically, employers having these types of work operations need only keep labels on containers as they are received; maintain material safety data sheets that are received, and give employees access to them; and provide information and training for employees. Employers do not have to have written hazard communication programs and lists of chemicals for these types of operations.

The limited coverage of laboratories and sealed container operations addresses the obligation of an employer to the workers in the operations involved, and does not affect the employer's duties as a distributor of chemicals. For example, a distributor may have warehouse operations where employees would be protected under the limited sealed container provisions. In this situation, requirements for obtaining and maintaining MSDSs are limited to providing access to those received with containers while the substance is in the workplace, and requesting MSDSs when employees request access for those not received with the containers. However, as a distributor of hazardous chemicals, that employer will still have responsibilities for providing MSDSs to downstream customers at the time of the first shipment and when the MSDS is updated. Therefore, although they may not be required for the employees in the work operation, the distributor may, nevertheless, have to have MSDSs to satisfy other requirements of the rule.

[Document index (top of page)]

- "Identify Responsible Staff"

Hazard communication is going to be a continuing program in your facility. Compliance with the HCS is not a "one shot deal." In order to have a successful program, it will be necessary to assign responsibility for both the initial and ongoing activities that have to be undertaken to comply with the rule. In some cases, these activities may already be part of current job assignments. For example, site supervisors are frequently responsible for on-the-job training sessions. Early identification of the responsible employees, and involvement of them in the development of your plan of action, will result in a more effective program design. Evaluation of the effectiveness of your program will also be enhanced by involvement of affected employees.

For any safety and health program, success depends on commitment at every level of the organization. This is particularly true for hazard communication, where success requires a change in behavior. This will only occur if employers understand the program, and are committed to its success, and if employees are motivated by the people presenting the information to them.

[Document index (top of page)]

This version of the OSHA HazCom Standard is no longer valid. It is presented here solely for historical purposes and has been replaced by a new version effective May 25, 2012. The subjects of the Appendices have also changed. - "Identify Hazardous Chemicals in the Workplace."

Keep informed about workplace hazards with proper labeling techniques and safety posters available from Safety Emporium.

The standard requires a list of hazardous chemicals in the workplace as part of the written hazard communication program. The list will eventually serve as an inventory of everything for which an MSDS must be maintained. At this point, however, preparing the list will help you complete the rest of the program since it will give you some idea of the scope of the program required for compliance in your facility.

The best way to prepare a comprehensive list is to survey the workplace. Purchasing records may also help, and certainly employers should establish procedures to ensure that in the future purchasing procedures result in MSDSs being received before a material is used in the workplace.

The broadest possible perspective should be taken when doing the survey. Sometimes people think of "chemicals" as being only liquids in containers. The HCS covers chemicals in all physical forms - liquids, solids, gases, vapors, fumes, and mists - whether they are "contained" or not. The hazardous nature of the chemical and the potential for exposure are the factors which determine whether a chemical is covered. If it's not hazardous, it's not covered. If there is no potential for exposure (e.g., the chemical is inextricably bound and cannot be released), the rule does not cover the chemical.

Look around. Identify chemicals in containers, including pipes, but also think about chemicals generated in the work operations. For example, welding fumes, dusts, and exhaust fumes are all sources of chemical exposures. Read labels provided by suppliers for hazard information. Make a list of all chemicals in the workplace that are potentially hazardous. For your own information and planning, you may also want to note on the list the location(s) of the products within the workplace, and an indication of the hazards as found on the label. This will help you as you prepare the rest of your program.

Paragraph (b) of this section, scope and application, includes exemptions for various chemicals or workplace situations. After compiling the complete list of chemicals, you should review paragraph (b) of this section to determine if any of the items can be eliminated from the list because they are exempted materials. For example, food, drugs, and cosmetics brought into the workplace for employee consumption are exempt. So rubbing alcohol in the first aid kit would not be covered.

Once you have compiled as complete a list as possible of the potentially hazardous chemicals in the workplace, the next step is to determine if you have received material safety data sheets for all of them. Check your files against the inventory you have just compiled. If any are missing, contact your supplier and request one. It is a good idea to document these requests, either by copy of a letter or a note regarding telephone conversations. If you have MSDSs for chemicals that are not on your list, figure out why. Maybe you don't use the chemical anymore. Or maybe you missed it in your survey. Some suppliers do provide MSDSs for products that are not hazardous. These do not have to be maintained by you.

You should not allow employees to use any chemicals for which you have not received an MSDS. The MSDS provides information you need to ensure proper protective measures are implemented prior to exposure.

[Document index (top of page)]

- "Preparing and Implementing a Hazard Communication Program".

- "Labels and Other Forms of Warning"

Get your GHS-compliant labels and signs from Safety Emporium.

In-plant containers of hazardous chemicals must be labeled, tagged, or marked with the identity of the material and appropriate hazard warnings. Chemical manufacturers, importers, and distributors are required to ensure that every container of hazardous chemicals they ship is appropriately labeled with such information and with the name and address of the producer or other responsible party. Employers purchasing chemicals can rely on the labels provided by their suppliers. If the material is subsequently transferred by the employer from a labeled container to another container, the employer will have to label that container unless it is subject to the portable container exemption. See paragraph (f) of this section for specific labeling requirements.

The primary information to be obtained from an OSHA-required label is an identity for the material, and appropriate hazard warnings. The identity is any term which appears on the label, the MSDS, and the list of chemicals, and thus links these three sources of information. The identity used by the supplier may be a common or trade name ("Black Magic Formula"), or a chemical name (1,1,1,-trichloroethane). The hazard warning is a brief statement of the hazardous effects of the chemical ("flammable," "causes lung damage"). Labels frequently contain other information, such as precautionary measures ("do not use near open flame"), but this information is provided voluntarily and is not required by the rule. Labels must be legible, and prominently displayed. There are no specific requirements for size or color, or any specified text.

With these requirements in mind, the compliance officer will be looking for the following types of information to ensure that labeling will be properly implemented in your facility:

- Designation of person(s) responsible for ensuring labeling of in-plant containers;

- Designation of person(s) responsible for ensuring labeling of any shipped containers;

- Description of labeling system(s) used;

- Description of written alternatives to labeling of in-plant containers (if used); and,

- Procedures to review and update label information when necessary.

[Document index (top of page)]

This version of the OSHA HazCom Standard is no longer valid. It is presented here solely for historical purposes and has been replaced by a new version effective May 25, 2012. The subjects of the Appendices have also changed. - Designation of person(s) responsible for ensuring labeling of in-plant containers;

- "Material Safety Data Sheets"

Chemical manufacturers and importers are required to obtain or develop a material safety data sheet for each hazardous chemical they produce or import. Distributors are responsible for ensuring that their customers are provided a copy of these MSDSs. Employers must have an MSDS for each hazardous chemical which they use. Employers may rely on the information received from their suppliers. The specific requirements for material safety data sheets are in paragraph (g) of this section. There is no specified format for the MSDS under the rule, although there are specific information requirements. OSHA has developed a non-mandatory format, OSHA Form 174, which may be used by chemical manufacturers and importers to comply with the rule. The MSDS must be in English. You are entitled to receive from your supplier a data sheet which includes all of the information required under the rule. If you do not receive one automatically, you should request one. If you receive one that is obviously inadequate, with, for example, blank spaces that are not completed, you should request an appropriately completed one. If your request for a data sheet or for a corrected data sheet does not produce the information needed, you should contact your local OSHA Area Office for assistance in obtaining the MSDS.

The role of MSDSs under the rule is to provide detailed information on each hazardous chemical, including its potential hazardous effects, its physical and chemical characteristics, and recommendations for appropriate protective measures. This information should be useful to you as the employer responsible for designing protective programs, as well as to the workers. If you are not familiar with material safety data sheets and with chemical terminology, you may need to learn to use them yourself. A glossary of MSDS terms may be helpful in this regard [ILPI says: Try our MSDS HyperGlossary, the best such resource]. Generally speaking, most employers using hazardous chemicals will primarily be concerned with MSDS information regarding hazardous effects and recommended protective measures. Focus on the sections of the MSDS that are applicable to your situation.

MSDSs must be readily accessible to employees when they are in their work areas during their workshifts. This may be accomplished in many different ways. You must decide what is appropriate for your particular workplace. Some employers keep the MSDSs in a binder in a central location (e.g., in the pick-up truck on a construction site). Others, particularly in workplaces with large numbers of chemicals, computerize the information and provide access through terminals. As long as employees can get the information when they need it, any approach may be used. The employees must have access to the MSDSs themselves - simply having a system where the information can be read to them over the phone is only permitted under the mobile worksite provision, paragraph (g)(9) of this section, when employees must travel between workplaces during the shift. In this situation, they have access to the MSDSs prior to leaving the primary worksite, and when they return, so the telephone system is simply an emergency arrangement.

In order to ensure that you have a current MSDS for each chemical in the plant as required, and that employee access is provided, the compliance officers will be looking for the following types of information in your written program:

- Designation of person(s) responsible for obtaining and maintaining the MSDSs;

- How such sheets are to be maintained in the workplace (e.g., in notebooks in the work area(s) or in a computer with terminal access),

and how employees can obtain access to them when they are in their work area during the work shift;

- Procedures to follow when the MSDS is not received at the time of the first shipment;

- For producers, procedures to update the MSDS when new and significant health information is found; and,

- Description of alternatives to actual data sheets in the workplace, if used.

For employers using hazardous chemicals, the most important aspect of the written program in terms of MSDSs is to ensure that someone is responsible for obtaining and maintaining the MSDSs for every hazardous chemical in the workplace. The list of hazardous chemicals required to be maintained as part of the written program will serve as an inventory. As new chemicals are purchased, the list should be updated. Many companies have found it convenient to include on their purchase orders the name and address of the person designated in their company to receive MSDSs.

[Document index (top of page)]

This version of the OSHA HazCom Standard is no longer valid. It is presented here solely for historical purposes and has been replaced by a new version effective May 25, 2012. The subjects of the Appendices have also changed. - Designation of person(s) responsible for obtaining and maintaining the MSDSs;

- "Employee Information and Training"

Each employee who may be "exposed" to hazardous chemicals when working must be provided information and trained prior to initial assignment to work with a hazardous chemical, and whenever the hazard changes. "Exposure" or "exposed" under the rule means that "an employee is subjected to a hazardous chemical in the course of employment through any route of entry (inhalation, ingestion, skin contact or absorption, etc.) and includes potential (e.g., accidental or possible) exposure." See paragraph (h) of this section for specific requirements. Information and training may be done either by individual chemical, or by categories of hazards (such as flammability or carcinogenicity). If there are only a few chemicals in the workplace, then you may want to discuss each one individually. Where there are large numbers of chemicals, or the chemicals change frequently, you will probably want to train generally based on the hazard categories (e.g., flammable liquids, corrosive materials, carcinogens). Employees will have access to the substance-specific information on the labels and MSDSs.

Information and training is a critical part of the hazard communication program. Information regarding hazards and protective measures are provided to workers through written labels and material safety data sheets. However, through effective information and training, workers will learn to read and understand such information, determine how it can be obtained and used in their own workplaces, and understand the risks of exposure to the chemicals in their workplaces as well as the ways to protect themselves. A properly conducted training program will ensure comprehension and understanding. It is not sufficient to either just read material to the workers, or simply hand them material to read. You want to create a climate where workers feel free to ask questions. This will help you to ensure that the information is understood. You must always remember that the underlying purpose of the HCS is to reduce the incidence of chemical source illnesses and injuries. This will be accomplished by modifying behavior through the provision of hazard information and information about protective measures. If your program works, you and your workers will better understand the chemical hazards within the workplace. The procedures you establish regarding, for example, purchasing, storage, and handling of these chemicals will improve, and thereby reduce the risks posed to employees exposed to the chemical hazards involved. Furthermore, your workers' comprehension will also be increased, and proper work practices will be followed in your workplace.

If you are going to do the training yourself, you will have to understand the material and be prepared to motivate the workers to learn. This is not always an easy task, but the benefits are worth the effort. More information regarding appropriate training can be found in OSHA Publication No. 2254 which contains voluntary training guidelines prepared by OSHA's Training Institute. A copy of this document is available from OSHA's Publications Office at (202) 219-4667. [ ILPI Says: follow that link we just gave you]. In reviewing your written program with regard to information and training, the following items need to be considered:

- Designation of person(s) responsible for conducting training;

- Format of the program to be used (audiovisuals, classroom instruction, etc.);

- Elements of the training program (should be consistent with the elements in paragraph (h) of this section); and,

- Procedure to train new employees at the time of their initial assignment to work with a hazardous chemical, and to train employees when a new hazard is introduced into the workplace.

The written program should provide enough details about the employer's plans in this area to assess whether or not a good faith effort is being made to train employees. OSHA does not expect that every worker will be able to recite all of the information about each chemical in the workplace. In general, the most important aspects of training under the HCS are to ensure that employees are aware that they are exposed to hazardous chemicals, that they know how to read and use labels and material safety data sheets, and that, as a consequence of learning this information, they are following the appropriate protective measures established by the employer. OSHA compliance officers will be talking to employees to determine if they have received training, if they know they are exposed to hazardous chemicals, and if they know where to obtain substance-specific information on labels and MSDSs.

The rule does not require employers to maintain records of employee training [ILPI says: Emphasis ours. Note there are likely to be compelling liability issues that should encourage such recordkeeping; web-based training provides an easily auditable record.], but many employers choose to do so. This may help you monitor your own program to ensure that all employees are appropriately trained. If you already have a training program, you may simply have to supplement it with whatever additional information is required under the HCS. For example, construction employers that are already in compliance with the construction training standard (29 CFR 1926.21) will have little extra training to do.

An employer can provide employees information and training through whatever means are found appropriate and protective. Although there would always have to be some training on-site (such as informing employees of the location and availability of the written program and MSDSs), employee training may be satisfied in part by general training about the requirements of the HCS and about chemical hazards on the job which is provided by, for example, trade associations, unions, colleges, and professional schools. In addition, previous training, education and experience of a worker may relieve the employer of some of the burdens of informing and training that worker. Regardless of the method relied upon, however, the employer is always ultimately responsible for ensuring that employees are adequately trained. If the compliance officer finds that the training is deficient, the employer will be cited for the deficiency regardless of who actually provided the training on behalf of the employer.

[Document index (top of page)]

This version of the OSHA HazCom Standard is no longer valid. It is presented here solely for historical purposes and has been replaced by a new version effective May 25, 2012. The subjects of the Appendices have also changed. - Designation of person(s) responsible for conducting training;

- "Other Requirements"

In addition to these specific items, compliance officers will also be asking the following questions in assessing the adequacy of the program:

- Does a list of the hazardous chemicals exist in each work area or at a central location?

- Are methods the employer will use to inform employees of the hazards of non-routine tasks outlined?

- Are employees informed of the hazards associated with chemicals contained in unlabeled pipes in their work areas?

- On multi-employer worksites, has the employer provided other employers with information about labeling systems and precautionary measures

where the other employers have employees exposed to the initial employer's chemicals?

- Is the written program made available to employees and their designated representatives?

- If your program adequately addresses the means of communicating information to employees in your workplace, and provides answers to the basic questions outlined above, it will be found to be in compliance with the rule.

- Does a list of the hazardous chemicals exist in each work area or at a central location?

Many of our visitors use these weather-resistant SDS storage boxes like this one. We have 3 different sizes available at Safety Emporium.All workplaces where employees are exposed to hazardous chemicals must have a written plan which describes how the standard will be implemented in that facility. Preparation of a plan is not just a paper exercise - all of the elements must be implemented in the workplace in order to be in compliance with the rule. See paragraph (e) of this section for the specific requirements regarding written hazard communication programs. The only work operations which do not have to comply with the written plan requirements are laboratories and work operations where employees only handle chemicals in sealed containers. See paragraph (b) of this section, scope and application, for the specific requirements for these two types of workplaces.

The plan does not have to be lengthy or complicated. It is intended to be a blueprint for implementation of your program - an assurance that all aspects of the requirements have been addressed.

Many trade associations and other professional groups have provided sample programs and other assistance materials to affected employers. These have been very helpful to many employers since they tend to be tailored to the particular industry involved. You may wish to investigate whether your industry trade groups have developed such materials.

Although such general guidance may be helpful, you must remember that the written program has to reflect what you are doing in your workplace. Therefore, if you use a generic program it must be adapted to address the facility it covers. For example, the written plan must list the chemicals present at the site, indicate who is to be responsible for the various aspects of the program in your facility, and indicate where written materials will be made available to employees.

If OSHA inspects your workplace for compliance with the HCS, the OSHA compliance officer will ask to see your written plan at the outset of the inspection. In general, the following items will be considered in evaluating your program.

The written program must describe how the requirements for labels and other forms of warning, material safety data sheets, and employee information and training, are going to be met in your facility. The following discussion provides the type of information compliance officers will be looking for to decide whether these elements of the hazard communication program have been properly addressed:

This version of the OSHA HazCom Standard is no longer valid. It is presented here solely for historical purposes and has been replaced by a new version effective May 25, 2012. The subjects of the Appendices have also changed. [Document index (top of page)]

- "Labels and Other Forms of Warning"

- "Checklist for Compliance"

The following checklist will help to ensure you are in compliance with the rule:

Obtained a copy of the rule Read and understood the requirements Assigned responsibility for tasks Prepared an inventory of chemicals Ensured containers are labeled Obtained MSDS for each chemical Prepared written program Made MSDSs available to workers Conducted training of workers Established procedures to maintain current program Established procedures to evaluate effectiveness [Document index (top of page)]

This version of the OSHA HazCom Standard is no longer valid. It is presented here solely for historical purposes and has been replaced by a new version effective May 25, 2012. The subjects of the Appendices have also changed. - "Further Assistance"

Major chain restaurants get their kitchen safety compliance products from Safety Emporium. Just sayin'…If you have a question regarding compliance with the HCS, you should contact your local OSHA Area Office for assistance. In addition, each OSHA Regional Office has a Hazard Communication Coordinator who can answer your questions. Free consultation services are also available to assist employers, and information regarding these services can be obtained through the Area and Regional offices as well.

The telephone number for the OSHA office closest to you should be listed in your local telephone directory. If you are not able to obtain this information [ILPI says: follow that hyperlink in the previous paragraph!], you may contact OSHA's Office of Information and Consumer Affairs at (202) 219-8151 for further assistance in identifying the appropriate contacts.

[52 FR 31877, Aug. 24, 1987; 52 FR 46080, Dec. 4, 1987; 53 FR 15035, Apr. 27, 1988; 54 FR 6888, Feb. 15, 1989; 54 FR 24334, June 7, 1989; 59 FR 6170, Feb. 9, 1994; 59 FR 17479, April 13, 1994; 59 FR 65947, Dec. 22, 1994; 61 FR 5507, Feb. 13, 1996; 61 FR 9227, March 7, 1996]

[Document index (top of page)]

[Previous: Appendix D] | Top of Document | [29 CFR 1910.1200]

The original, public domain, OSHA version of this document is available courtesy of the Internet Wayback Machine at https://web.archive.org/web/20120926212550/http://www.osha.gov/dsg/hazcom/hazcom_appe_1994.html.