Find all of your laboratory and workplace safety supplies at Safety Emporium!

Acute Toxicity |

Glossary Index |

AFI |

| MSDS Topics |

Free Sites | FAQ's | Regulations | Glossary | Software | Suppliers |

| Books | Forum | Poll | Fun stuff | Quiz | Store | |

| Understand your MSDS with the MS-Demystifier | Search ALL our MSDS info | |||||

Administrative controls (or work practice controls) are changes in work procedures such as written safety policies, rules, supervision, schedules, and training with the goal of reducing the duration, frequency, and severity of exposure to hazardous chemicals or situations.

Those who work with hazardous chemicals in the workplace should already be familiar with the administrative controls required under 29 CFR 1910.1200, the OSHA Hazard Communication Standard. The HazCom standard requires that employers provide information and training about chemical hazards in the workplace. Other OSHA standards address environmental and medical surveillance such as work place inspections, equipment preventive maintenance, and exposure monitoring. In addition, laboratory workers have written policies and procedures (a "chemical hygiene plan") that details safe work practices under 29 CFR 1910.1450, the Laboratory Standard.

Although administrative controls can (and should) always be used to control employee exposure, they are prone to human error and can not be relied upon to reduce exposure all the time. Additional control mechanisms such as substitution of less hazardous materials/procedures, engineering controls and personal protective equipment (PPE) may be required to address employee exposure to the hazard(s).

Anti-skid floor marking signs from Safety Emporium can help enforce your administrative control program.

Some specific examples of administrative controls include:

Recognize that administrative, engineering, and other types of controls (including PPE) are not mutually exclusive. Employers may need to use multiple types of controls to prevent employee overexposure.

NOTE: We may collect a share of sales or other compensation from the links in the following list:

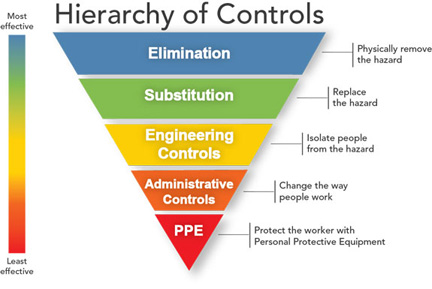

The preferred methods for reducing chemical exposure, in order of general effectiveness, are illustrated in this diagram:

Specifically, these steps are:

Recognize that an effective risk reduction plan utilizes all all of these steps to reduce the level of risk to as low as reasonably achievable (ALARA). Relying on just one means that a single failure can result in a potentially harmful employee exposure or injury.

The exact words "administrative controls" do not usually appear on Safety Data Sheets although some specific work practices may be suggested. If present, they would be found in Section 8 (exposure controls/personal protection). Regardless, administrative controls are key to the reduction/elimination of hazards and no worker safety program is complete without these.

Be compliant with confined space products from Safety Emporium.

See also: ALARA, engineering controls, PPE.

Additional definitions from Google and OneLook.

Entry last updated: Wednesday, February 16, 2022. This page is copyright 2000-2025 by ILPI. Unauthorized duplication or posting on other web sites is expressly prohibited. Send suggestions, comments, and new entry desires (include the URL if applicable) to us by email.

Disclaimer: The information contained herein is believed to be true and accurate, however ILPI makes no guarantees concerning the veracity of any statement. Use of any information on this page is at the reader's own risk. ILPI strongly encourages the reader to consult the appropriate local, state and federal agencies concerning the matters discussed herein.