|

|

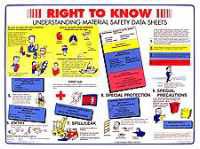

| MSDS Topics |

Free Sites | FAQ's | Regulations | Glossary | Software | Suppliers |

| Books | Forum | Poll | Fun stuff | Quiz | Store | |

| MSDS and safety supplies | Search ALL our MSDS info | |||||

| |||

|

|

|

|

| Title: 07/11/1989 - The hazard warning labels attached to shipments of solder. | |

| Record Type: Interpretation | Standard Number: 1910.1200 |

July 11, 1989

Mr. Carl Seymour

Administrator and Credit Manager

Borde Communications

Valsayn Road, CUREPE

Post Office Box 897

Port-of-Spain

TRINIDAD

Dear Mr. Seymour:

|

This is in response to your letter of January 12, addressed to the National Bureau of Standards, regarding the hazard warning labels attached to a shipment of solder your company received. The National Institute of Standards and Technology (formerly the National Bureau of Standards) forwarded your letter to the Occupational Safety and Health Administration (OSHA). Please accept our apology for the long delay in this response to you. In your letter, you mention that for a number of years you have been purchasing solder products from the United States but that recently, shipments of the solder materials have contained warning labels that indicated that the inhalation of solder fumes "could be harmful and could lead to birth defects, etc." On November 25, 1985, OSHA's Hazard Communication Standard (HCS) became effective. The standard requires that chemical manufacturers and importers assess the hazards of the chemicals and products they sell. The HCS has recently been expanded to include all workers exposed to hazardous substances in all industrial sectors, not just those in the manufacturing sector covered under the original standard. |  Teach your employees about MSDS's with posters and pamphlets from Safety Emporium. |

OSHA's Hazard Communication Standard was promulgated to ensure that all employers receive the information they need to inform and train their employees properly on the hazardous substances they work with and to help design and put in place employee protection programs. It also provides necessary hazard information to employees, so they can participate in and support the protective measures in place at their workplaces.

Since November of 1985, therefore, manufacturers of hazardous substances in the United States have had to comply with the Agency's HCS as described above, and this is why shipments of solder you have been receiving from the U.S. have contained the warning labels you mentioned in your letter. With regard to your specific question on whether or not "standards exist for solder" and "if solder is in fact harmful" to one's health, OSHA has enforced, since 1981, its standard for occupational exposure to inorganic lead. Solder contains, as you indicated in attachments to your letter, a large percentage of lead. During soldering operations, personnel risk being exposed to lead fume. OSHA's current standard for occupational exposure to lead during soldering operations is set at 50 micrograms lead per cubic meter of air (50mg/m3), measured as an 8-hour time weighted average exposure (e.g., employee exposure to lead in air, measured and averaged over an 8-hour work day). OSHA's Lead Standard sets requirements for the provision of environmental (workplace) monitoring, recordkeeping, employee education and training, medical surveillance, medical removal protection, hygiene facilities and other requirements that must be met by employers if their employee's exposure to lead exceeds the specified limits.

| In your letter, you also inquire as to the "harmful side effects experienced for the inhalation of solder flux fumes." "Solder flux" generally refers to a substance applied in soldering and brazing operations to portions of a surface to be joined and which acts, with the application of heat, to prevent oxide formation and to facilitate the flow of solder. Fluxes may contain hydrazine salts and/or other harmful or toxic compounds, exposure to which may in themselves represent a health hazard, depending again on the duration and amount (or dose) of the exposure. Information on the chemical composition of any solder flux compounds that you may be using should be obtainable from the labels on the MSDS that comes with the fluxes, if manufactured in the United States. In order for you to know if these or any other types of harmful exposures are occurring in your workplace, you may wish to have a competent occupational health professional, such as an industrial hygienist, perform a survey of your workplace and develop an occupational health program for your employees. We are unable to tell you what harmful exposures, if any, are occurring or could occur at your worksite; such an evaluation can only be made after an on-site safety and health survey has been performed. In the interest of safety and health survey has been performed the safety and health of yourself and your employees, you may want to arrange for such an evaluation to take place. The results of an on-site safety and health survey would enable you to develop a safety and health program specific to your worksite and give you necessary information to provide a safe and healthful workplace, free from recognized hazards and preventative of potential occupational safety and health risks. |  If you work around lead dust, consider a complete supplied air respirator system like this one from Safety Emporium. |

Sincerely,

Patricia K. Clark, Acting Director

Directorate of Compliance Programs

The official, public domain, OSHA version of this document is available at http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=INTERPRETATIONS&p_id=19822&p_text_version=FALSE