|

Safety Emporium is a proud sponsor of this site. |

|

Home Page --> Tutorial Lesson 10, Making a Test Tube

|

|

Safety Emporium is a proud sponsor of this site. |

|

Home Page --> Tutorial Lesson 10, Making a Test Tube

|

| Tutorial Lesson 10, Making a Test Tube | |

|---|---|

| Lesson 9 (Annealing) |

Lesson 11 (Butt Seals) |

| Tip: Roll the glass point (after cooling) on a flat surface. If your rotation is good the glass tube and "point" will be centered with no wobble. |

| Tip: This is a good time to practice the process of blowing glass. Try different flame and blow pressure combinations to see how the glass responds. Position the glass tube in different regions or angles of the flame. Glassblowers will use combinations of heat, flame size and angle, gravity and pressure in shaping glass. With experience you will learn how much or hard to blow air, when to let gravity work for you, and even when to inhale to produce that certain look or shape. |

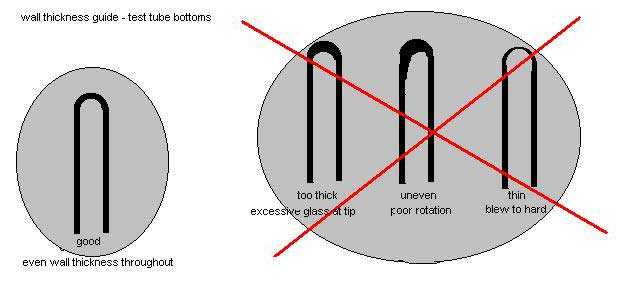

In virtually all cases you should strive to maintain an even wall thickness throughout your glass project. If the glass tube is not rotated or heated evenly the glass wall may become lopsided, thick on one side and thin on the other. It will be difficult to control the glass being worked if the difference in wall thickness is too great. The uneven wall thickness will not heat to the working temperature uniformly, resulting in hot spots (thin wall) that blow out and cold spots (heavy wall) that do not move. Even wall thickness will help you produce structurally sound glass apparatus.

The importance of good rotation should now be apparent!

Disclaimer: Glassblowing has inherent hazards that can result in burns, cuts, injuries or even death. While every effort has been made to convey best safety practices, the materials presented herein can not anticipate every possible risk or hazard associated with a given glassblowing activity. The reader is responsibile for assessing and mitigating any and all such hazards or risks before commencing any activity connected with his or her use of these materials. Neither the author nor ILPI assumes responsibility or liability for injuries, losses, claims or damages to the reader or other parties that may result from the use or misuse of these materials.

by Joe Walas and/or ILPI, all rights reserved unless otherwise stated. Unauthorized duplication or posting on other web sites is expressly prohibited. Send suggestions and comments (include the URL if applicable) to us by email.